-

nilshantideep@gmail.com -

+91-9595331313 - Send SMS

- Send Email

- GST No. 27BIKPS5417A3Z8

| Business Type | Manufacturer, Exporter, Supplier, Trader, Distributor, Importer, Buying House |

| Power Source | Electric |

| Operating Pressure | 2 to 200 Bar |

| Usage | Industrial |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Mixing Ratio

0.1/1 to 20/1

Viscosity Range

30 to 5000 cps

Flow Rate

50 to 1500 cc/min

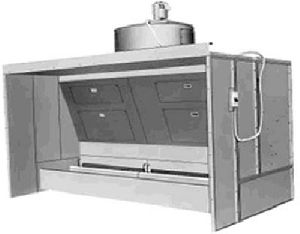

we are acknowledged as the prime distributor & service provider of electronic two component equipment based on a constant output that is combined with controlled frequency modulated hardener out. Our equipment has upgraded manual, robot, and automatic system that work along with equipment such as electrostatic spray painting equipment, hvlp spray painting equipment, airless spray painting equipment, and many more. Our electronic two component equipment can easily handle various types of fluid like primers, varnish, epoxy, lacquers, etc.

works efficiently with :

- manual, automatic & robotic systems

- hvlp spray painting equipment

- air assisted airless spray painting equipment

- airless spray painting equipment

- electrostatic spray painting equipment

Technical Specification

| Type of mixing | Manual | Mechanical | Electronic |

| Ratio Accuracy | +/- 10% | +/- 4% | +/- 1% |

| Unused mixed materials | Large | Little | Very Little |

| Traceability | No | No | Yes |

| Mixing Quality | Low | Very Good | Excellent |

| Preparation time | Long | Short | Very Short |

| Safety of Application | Low | Medium | Excellent |

Technical Specification 02

| Features | Benefits |

| Material characteristic automatic management: base, catalyst and solvents | Dosing +/- 1% and Repeatability +/- 0.5% |

| Automatic mix material fill | Quick start-up, product savings |

| Adaptable programming for each color | Ideal application for each color |

| Several flushing modes: production cycle, extended production stops, solvent-based materials | Perfect compatibility with production conditions evolutions |

| Fast mixing ratio accuracy by beakers | Visual control of the mixing dosing accuracy |

| Batch mode | To easily get small quantities of mixed materials for touch-up works |

| Autowash system | Off-production gun automatic monitoring |

| Multilingual display and integrated instruction manual | User-friendly and quick programming learning for the operator |

| All stainless steel construction | Compatible with new future materials (water-based products, etc...) |

| Numerical interface | Quick link with an on-line automate |

| Integrated spraying air management | Comfort and safety during color and solvent fill |

| Pneumatic emergency flushing | Perfect flushing in case of power supply cut-off |

| Design of the mixing plate | Easy maintenance and spare parts standardization |

| Robotic interface | Connection with an on-line automate |

| Remote controlling facility | Can be operated via remote sensing |

| Automatic Maintenance Alarm system | Easy Start-up & Maintenance |

| Ease Computer Connectivity | No. of Shift, No. of Component & more |

| User Friendly, Simple & Multi-Language Configuration | Data recording and recovery system |

Looking for "Electronic Two Component System" ?

Piece(s)